Description

Basic information

|

Standard |

AISI,ASTM,BS,DIN,GB,JIS |

Brand Name |

JEC |

|

Place of orgin |

Malaysia, Vietnam, South Korea |

Surface Treatment |

Light oil,Unoil, Dry,Chromate Passivated, Non-chromate Passivated |

|

Grade |

DX51D SGCC SGHC G550 |

Coating |

Z10-Z29、Z30-Z40、Galvanized coating |

|

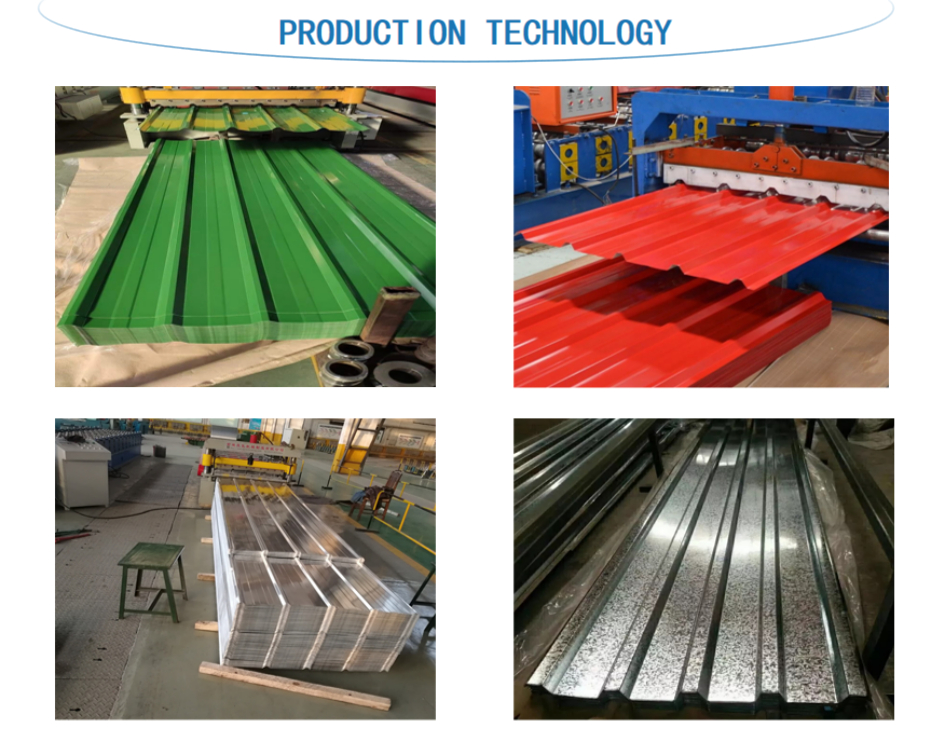

Technique |

Hot Rolled |

Full Hard |

|

|

Application |

Building Material |

Length |

Customer's Requirement |

|

Width |

Under 1500mm |

Coil ID |

508mm-610mm |

|

Thickness |

0.13-4.0mm |

Package |

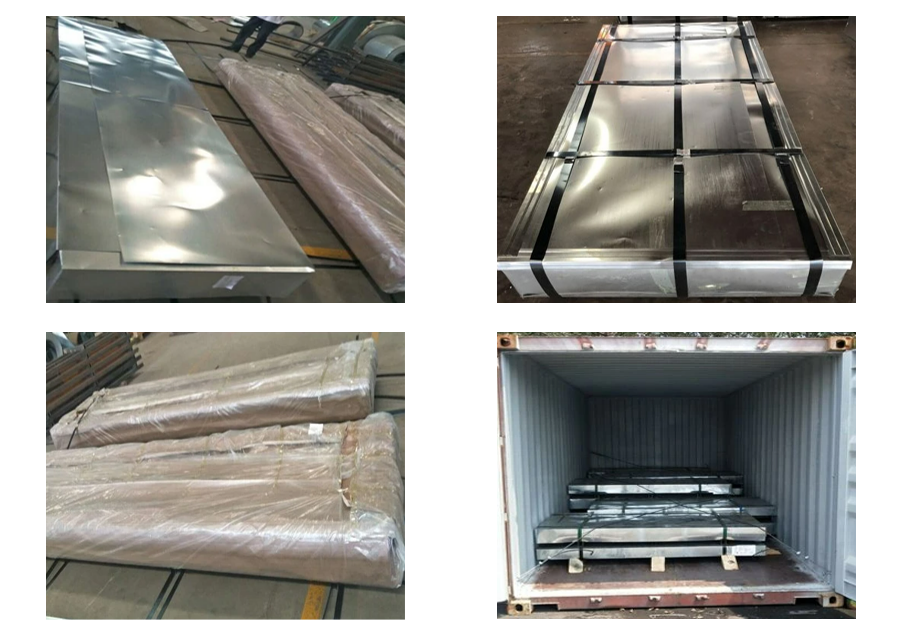

Seaworthy package plastic film + waterproof paper + steel plate + packaging steel |

|

Spangle Type |

Regular spangle,Minimal spangle,Zero spangle,Big spangle |

Delivery time |

15-25 days after we got T/T payment |

|

Tolerance |

± 1%, thickness: + / -0.02mm Width: + / -2mm |

Payment term |

30%TT Balance T/T and L/C both ok |

|

Zinc coating |

20-275G/M2 |

Trademark |

JEC |

|

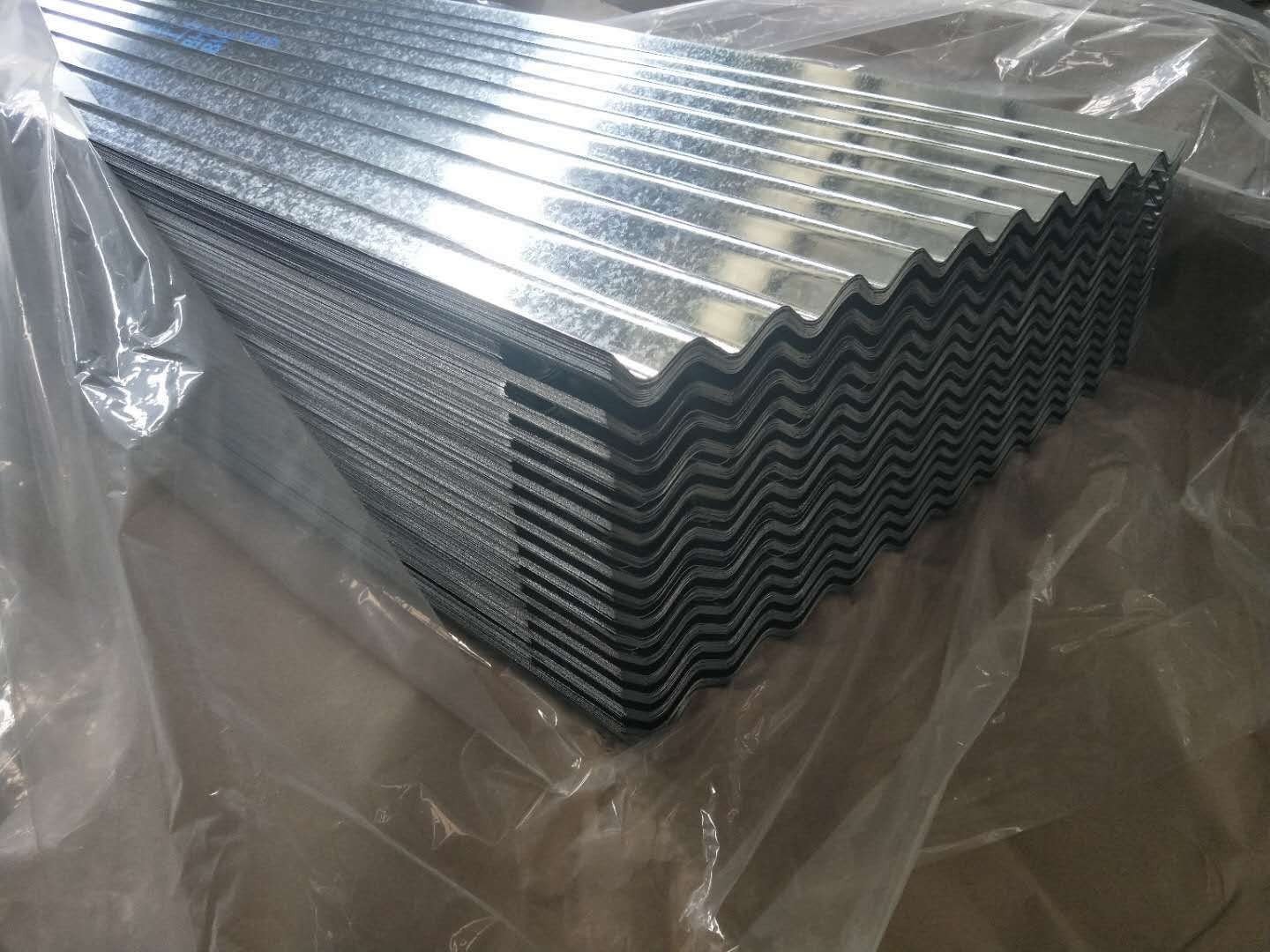

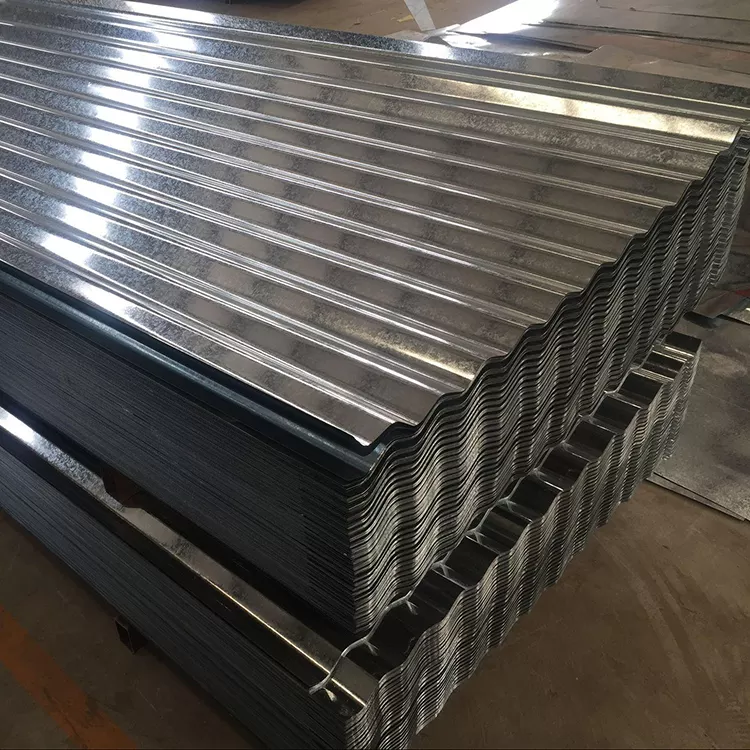

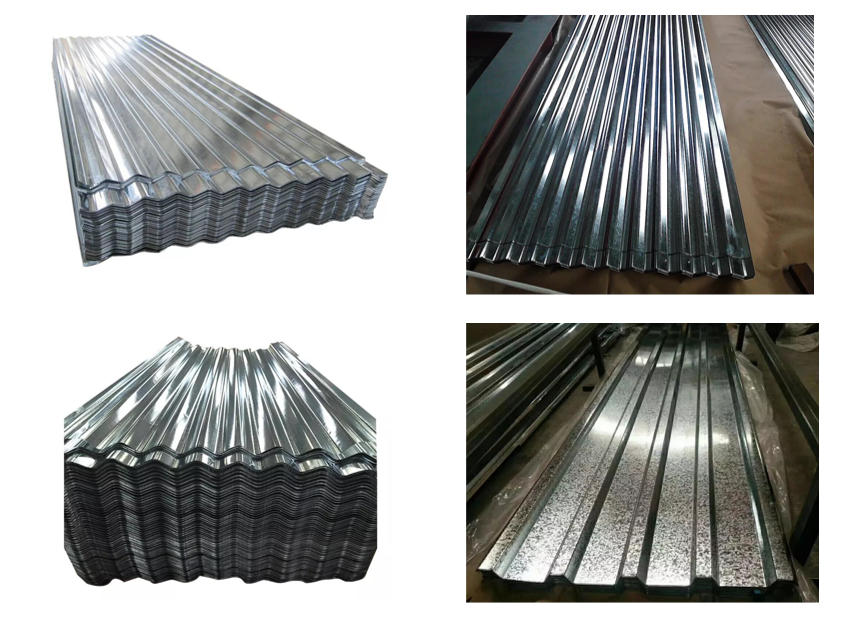

Product Name |

Galvanized Corrugated Steel Sheet |

HS Code |

721041 |

Product Description

|

Product |

Galvanized Corrugated Steel Sheet |

|

Grade |

DX51D SGCC SGHC G550 |

|

Standard |

AISI,ASTM,BS,DIN,GB,JIS |

|

Width |

Under 1500mm |

|

Thickness |

0.13-4.0mm |

|

Technique |

Hot Rolled |

|

Zinc coating |

20-275G/M2 |

|

Hardness |

Soft Hard(HRB60),Medium Hard(HRB60-85),Full Hard(HRB85-95) |

|

MOQ |

1 Metric Ton/Metric Tons |

|

Delivery time |

15-25 days after we got T/T payment |

|

Payment term |

30%TT Balance T/T and L/C both ok |

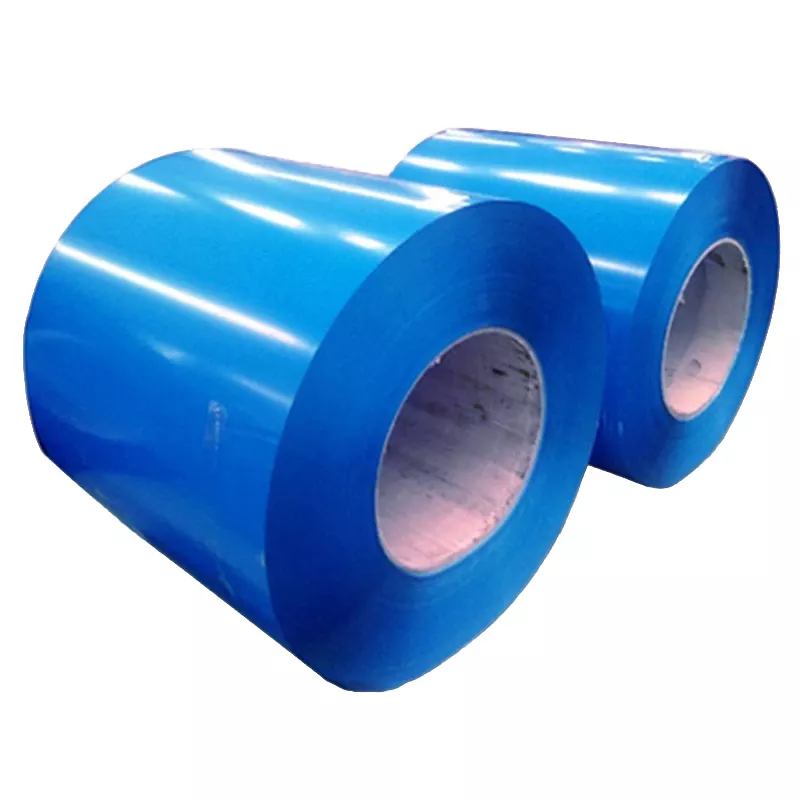

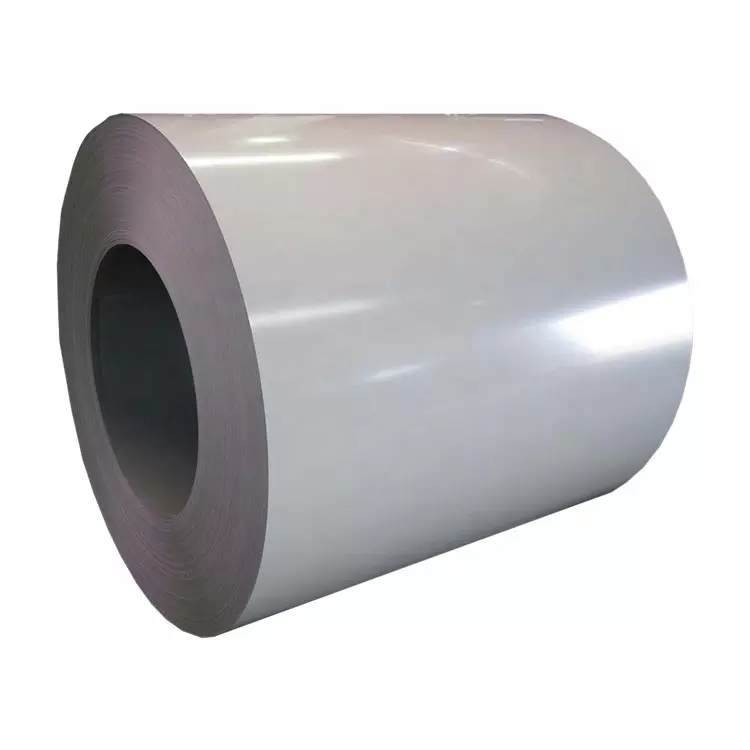

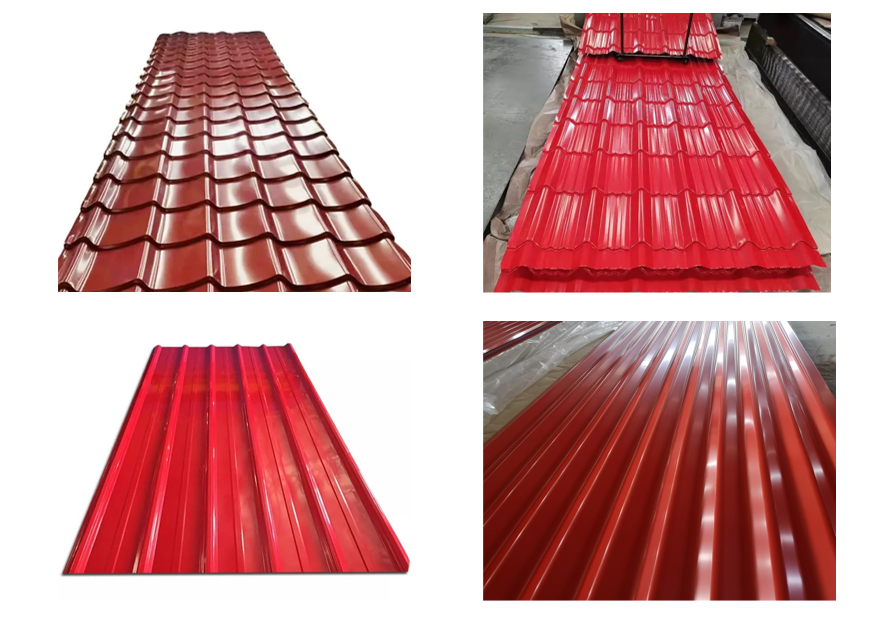

(1)Cold rolled substrate color coated steel sheet. The color sheet produced by the cold-rolled substrate has a smooth and beautiful appearance and has the processing property of the cold-rolled sheet;

(2)Hot-dip galvanized color coated steel sheet(prepainted galvanized steel sheet

The product obtained by coating an organic coating on a hot-dip galvanized steel sheet is a hot-dip galvanized color-coated plate. In addition to the protective effect of zinc, the hot-dip galvanized color-coated sheet also protects against rust and has a longer service life than hot-dip galvanized sheet;

(3)Hot-dip aluminum-zinc color coated sheet(prepainted galvalume steel sheet) Hot-dip aluminum-zinc steel sheets can also be used as color-coated substrates (55% AI-Zn and 5% AI-Zn);

(4)Electroplated zinc color coated sheet

The electro-galvanized sheet is used as the substrate, and the product obtained by baking with the organic coating is an electro-galvanized color-coated plate. It has a beautiful appearance and excellent processing properties, and therefore can be mainly used for home appliances, audio, steel furniture, interior decoration, and the like.

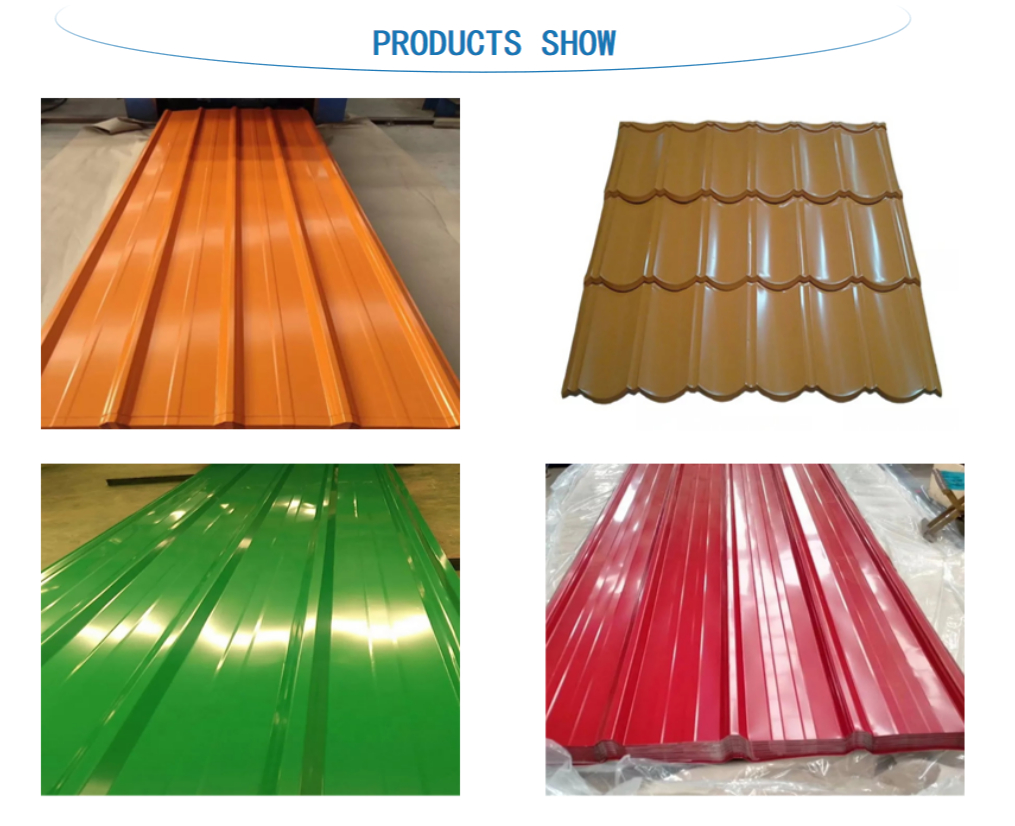

Characteristic

1. Outlook Beautiful and novel, rich colors, flexible combination, can be used in different building to express special original architectural styles in life.

2. Surface have been treated as galvanized and color coated. So it can anti-rain, anti- fire, anti-quake, So it has a long term life as 20-30 year and color just not fade.

3. Light weight: Easy to transport the material, short the time to finish the building, reduce worker's hard work, save much time and energy for human beings.

4. Smooth surface treatment, the dust will be easy taken off by the rain.

5. Environmental material, can be used many times, will do no hard to the our environment.

6. Prime anti-fire application, which is confirmed by GB50222-95 as difficult to fire as B

7. Impact resistance, strength is 250-300 times of common glass, 2-20times of tempered glass,89. 8.Energy saving: Keep summer cool, winter warm. Heat insulation effect is higher 7%-25% than that of the common glass, then heat loss is greatly reduced.

9. Insulation resistance: Corrugated sheet with obvious effect of noisy.

10. Light in weight, and have very good beatification vision effect.

Application

The color-coated coil with hot-dip galvanized steel as the base material is processed into corrugated board and polyurethane plywood, which is used to construct industrial and commercial roofs, walls and facades. There are mainly roof structures, rolling doors, kiosks, shutters, guard doors, street waiting rooms, ventilation ducts and other neighborhoods.

Attentions in Transportation and Storage:

1. Galvanized Steel Coils should be stored in neat and tidy environment to avoid possible corrosion

caused by all kinds of corrasive medium.

2. The ground for storage should be flat, without hard object, and with sufficient loading-bearing capacity.

3. Storage environment should be dry and ventilated. Avoiding storing outdoors or with dew or with

wide temp difference.

4. Coil could not be dragged lest the burr caused by slicing will scratch the coil surface underneath.

Coil should be handled with care, without hitting any hard object.